Here is something many plastic manufacturers who want to shift to sustainable alternatives are bound to welcome — a technology that produces granules out of bamboo that can be directly used on plastic-making machines to manufacture compostable products.

As everyone knows, bamboo is a non-wood biomass. Though a renewable resource that is widely grown and is being promoted under the National Bamboo Mission, it has not been commercially exploited as much as it should have been. Now technology may make that possible, giving bamboo growers much more value for their crop. Standalone machinery

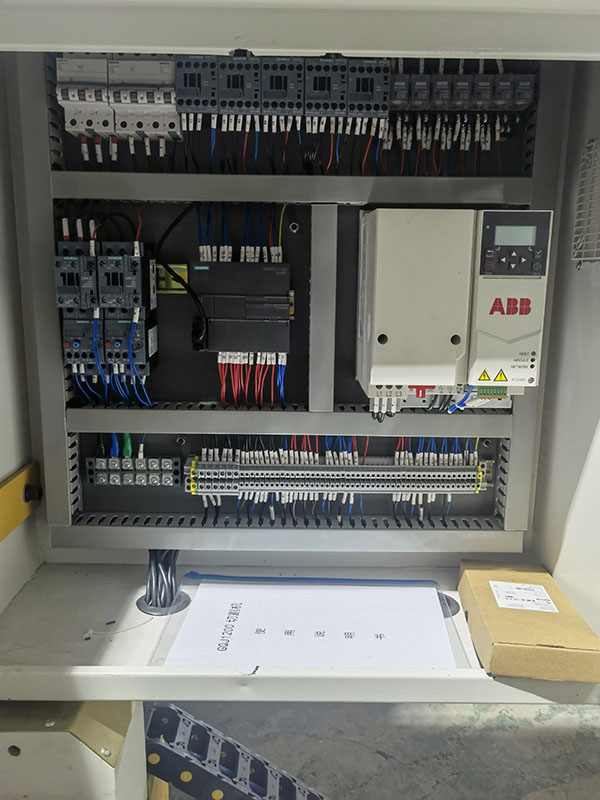

Noida-based social enterprise Bio Craft Innovation Pvt Ltd, known as IBANSS, has been incubating various technologies in this field with the help of the Indian Institute of Technology-Kanpur. Working along with HDFC Bank CSR, it is seeing interesting results in a pilot that is underway. The company makes bamboo granules and bamboo-based cellulose fibres.

CEO Anubhav Mittal explains, “Bio craft has developed a grafting technology that helps couple a bio polymer with plant fibre. We have designed reaction technology that helps polarise the polymer chains so that it can be made into composite bamboo fibre. In addition, our grafting is done using an organic material, therefore, once the product is discarded and comes in contact with soil, it starts biodegradation due to the presence of graft and bamboo fibre.”

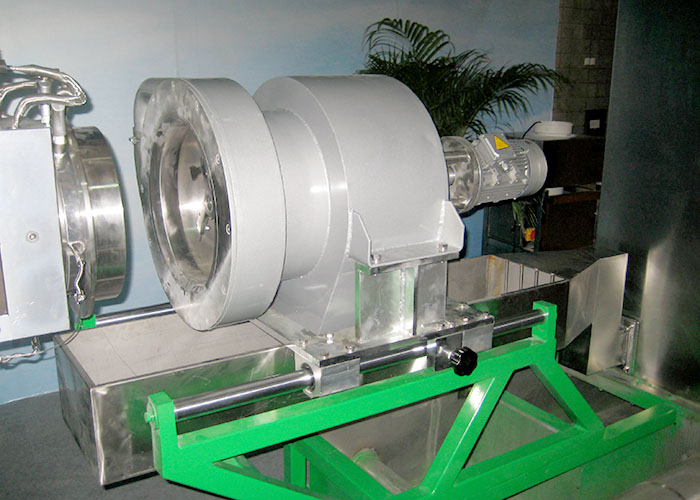

Mittal says the second important technology that has been developed is of mechanically extracting bamboo fibre. “Mechanical pulping is the oldest form of extraction of cellulose from wood or any biomass. What we have improvised in this is that we do not use any water while extraction. It is purely a mechanical process, and is achieved by beating the biomass at a very high rate to generate enough heat and kinetic energy that helps separate cellulose fibres in the wood matrix.”

The third important technology is the ability to extract cellulose from any source like bamboo, wood waste, and crop waste, among others. Through this, the company hopes to connect agriculture producers to the plastic industry, “creating a win-win situation but generating sustainable and rewarding industrial demand from the producers”, he says.

IBANSS was recently recognised by the Marico Innovation Foundation. Its materials can make all kinds of products like tableware and textile material that can be transformed into sustainable sanitary pads, home and kitchen textiles, compostable polyester, nylon fibres and yarn while building a sustainable future for farmers.

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

Plastic Bottle Shredder We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.